Sanshin Mining Ind. Co., Ltd.

Message

『Sanshin Mining contributes to the world’s beauty and cosmetics.』

The “Sanshin” in our name was named by Akimaro Misaki, our predecessor, in order to be a company that values the three “Shin”.

These are meaning “faith,” “faithfulness,” and “trust”.

As a manufacture of cosmetics materials, we are committed to contributing to the creation of cosmetics that makes people all over the world to enjoy beauty with peace of mind.

To this aim, we will continue to make every effort to have not only our business partners but also our users have “Shin” in our company.

Sanshin Mining’s Sericite Products

| FSE | FSE-S | FSN | NSP | JS-A | JS-1 | FMK | |

|---|---|---|---|---|---|---|---|

| Characteristics | Sanshin Miningʼs original standard grade |

Sanshin Miningʼs original low heavy metals and low bromide grade |

Sanshin Miningʼs original worldʼs smallest grade |

Sanshin Miningʼs original bromide grade |

Smooth feeling and high transparency | Moist feeling and matte feeling | Industrial grade※7 |

| Average Particle Size (μm) |

6~8 | 6~8 | 3~5 | 6~8 | 10~15 | 9~12 | 10~20 |

| Whiteness※1 | 90.0≦ | 90.0≦ | 90.0≦ | 90.0≦ | 90.0≦ | 90.0≦ | - |

| Loss on drying※2 (%) |

1.0≧ | 1.0≧ | 1.0≧ | 1.0≧ | 1.0≧ | 1.0≧ | 1.0≧ |

| Loss on ignition※3 (%) |

9.0≧ | 9.0≧ | 9.0≧ | 9.0≧ | 2.0≧※4 | 9.0≧ | - |

| Acid solubles※5 (%) |

2.0≧ | 2.0≧ | 2.0≧ | 2.0≧ | 2.0≧ | 2.0≧ | - |

| Lead※6 (ppm) |

10≧ | 10≧ | 10≧ | 10≧ | 10≧ | 10≧ | - |

| Arsenic※6 (ppm) |

3≧ | 2≧ | 3≧ | 3≧ | 2≧ | 2≧ | - |

| Antimony※6 (ppm) |

- | 20≧ | - | - | 5≧ | 10≧ | - |

| Cadmium※6 (ppm) |

- | 3≧ | - | - | 3≧ | 3≧ | - |

| Mercury※6 (ppm) |

- | 1≧ | - | - | 1≧ | 1≧ | - |

※1 : Hunter’s method

※2 : 5.0g, 105℃ Constant weight

※3 : JSQI 2006, Sericite Loss on drying

※4 : Apply with US FDA “〇73.1496 MICA(b)”

※5 : JSQI 2006, Sericite purity test(1)

※6 : Total dissolution analysis using atomic absorption spectrometer

※7 : Quality control items can be adapted to your requirements.

Process

1.Mining

Our highly skilled miners dig several tunnels to extract sericite of unparalleled quality.

↓

2.Removal of impurities and classification

Impurities are removed by our accumulated technologies and classified by separators to make products with the appropriate particle size.

↓

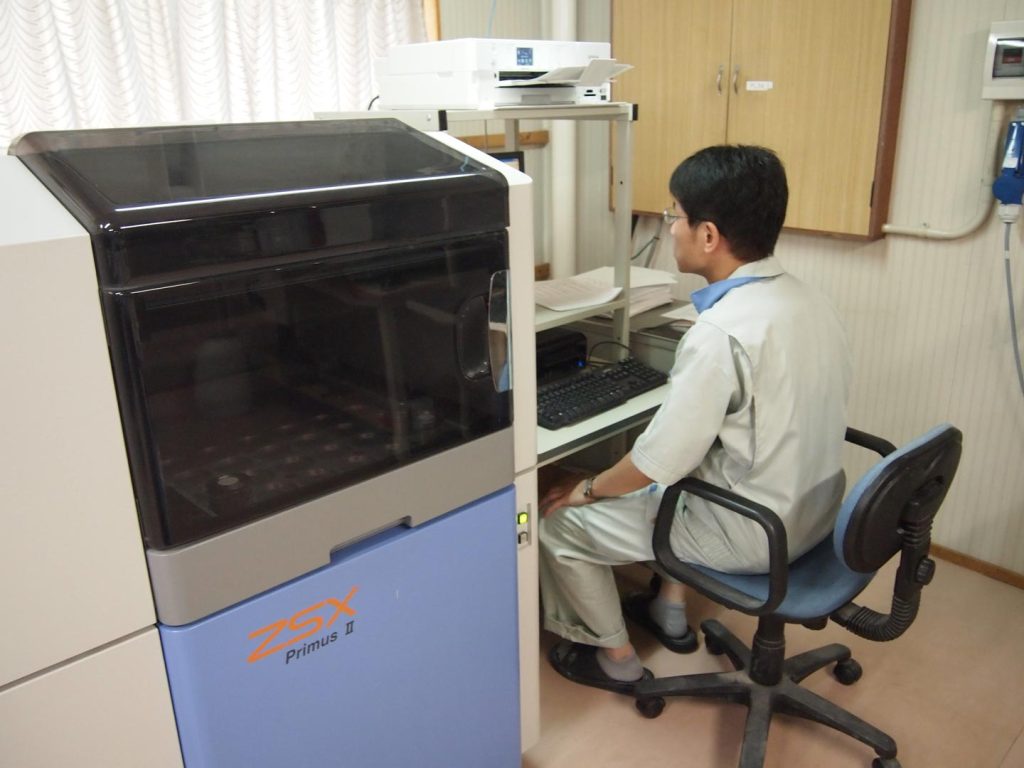

3.Analysis

For safety and reliability, all product batches are analyzed by specialized experts under strict protocols.

↓

4.Shipping

Every single shipment is checked and verified for any problems before shipping.

Overview

| Company Name | Sanshin Mining Ind. Co., Ltd. |

|---|---|

| President and CEO | Junichi Misaki |

| Capital | 30 million yen |

| Number of employees | 32 (including directors) |

| Business description | Mining and refining of sericite |

| Head Office | 3, Kamiawashiro Miyadaira, Furikusa, Toei-town, Kitashitara-county, Aichi-Pref 449-0213, Japan TEL: +81-536-78-5511 / FAX: +81-536-78-5005 |

| Major Banks | Bank of Mitsubishi UFJ,Toyohashi Branch Toyokawa Shinkin Bank, Toei Branch Aichi Bank, Shinshiro Branch Shoko Chukin Bank, Toyohashi Branch |

| Main Business Partners | JAPAN SERICITE Co. Kakuhachi Co.,LTD. Kosuge Co., Ltd. NIHON KOKEN KOGYO CO.,LTD. Bridgestone Corporation Miyoshi Kasei, Inc. Otsuka Chemical Co.,Ltd. Tokyo Zairyo Co., Ltd. (Titles omitted) (in no particular order) |

Board of Management

President & CEO Junichi Misaki

Joined the company in 1995

1999 Director, General Manager of Sales Planning Dept. and Deputy Manager of Mining Division

2006 Managing Director

2008- President & CEO

Director Nobuharu Suzuki

Joined the company in 1988

1999 Director, General Manager of Product Development Division (currently Research and Development Division)

2006 Managing Director

2008 Senior Managing Director

2023- Director

Director Tsunemitsu Kakumoto

2003- Director

Director Tomoko Misaki

2008 Corporate Auditor

2023- Director

Director Yukitaka Nishikawa

2023- Director

Corporate Auditor Yoko Saito

2023- Corporate Auditor

Experts perspective

Future development of sericite in the cosmetics field

The Only High Purity “Sericite” Mined in Japan – Encounter in Sanshin.

-Atsuko Morita, Phytotherapist-

High purity “Sericite” from Higashi Mikawa

My mother “Yasuko Morita” had been researching and studying soil and geology in Aichi pref, for many years.

She discovered that the sericite mined at Sanshin Mining, located in Toei-town, Aichi pref, is one of the rarest and most valuable high-purity sericite in the world.

Sanshin Mining has been mining sericite for about 80 years, and as of 2024, it is the only one of its kind in Japan.

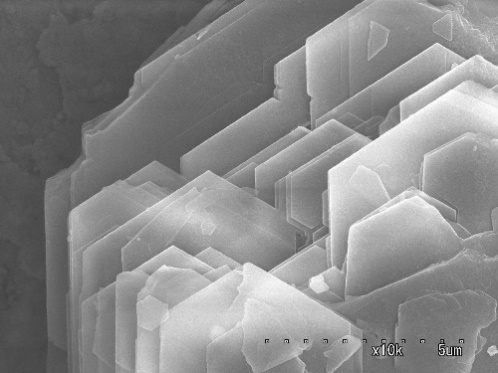

This sericite has the world’s smallest particle size (less than 5 µm) in a non-milling process using a wet classification process, and is of high purity with maximum removal of impurities.

The small particle size makes sericite with excellent physical properties and performance, and I have found it to be useful in our field of cosmetics.

First of all, in terms of physical properties, its small particle size makes it excellent in adsorption and fast in reaction speed.

In terms of performance, when processed as a coating, the coating film becomes uniform, and durability and weather resistance are improved. It also has a smooth texture and reduces friction with the painted surface.

Application of high-purity, fine-particle “sericite” in the cosmetics field

This feature makes it suitable for use as a base material for cosmetic packs.

The “Clay Pack” developed by Waphyto Co., Ltd. contains highly pure and fine sericite produced in Sanshin Mining, which gives it a silky smooth feel on the skin and reduces the burden on the skin. Furthermore, its excellent adsorptive properties allow it to tightly adhere to the skin and remove sebum stains and unwanted keratin. In addition, the excellent adsorption to the skin allows the functional plant extracts contained in the clay pack to approach the skin firmly.

This sericite from Sanshin Mining is used not only in the cosmetics field but also in various other fields, and is expected to be the subject of further research and development in the future.

Atsuko Morita

Phytotherapist

CEO, Saint-Louis International Inc.

CEO, Waphyto Co.

Atsuko Morita is a leading expert in “plant biomethodology,” which is a combination of phytotherapy systematized in France and herbology established in Japan.

He is engaged in a wide range of businesses from cosmetics to amenities and supplements.

He is also known as a pioneer of “Femtek” and “delicate zone care. In 2023, she was chosen by ELLE magazine as one of the “100 Women Who Will Change the World”.

Potential of Sericite as a High-Temperature Solid Lubricant

Tribology and Sericite

~Professor Hatsuhiko Usami, Meijo Univ~

Tribology is the science and technology of all phenomena that occur between surfaces in relative motion and affecting each other, such as lubrication, friction, wear, and lubrication.

Among these, I am conducting research on the theme of “Reduction of friction loss by surface heterogeneity that contributes to the construction of a society capable of sustainable development.

In terms of specific technologies involving familiar tribology, it is easy to recognize slider heads that read information on hard disks, brakes and tires of automobiles, and so on.

In addition, we are also involved in various other phenomena on different scales, such as “biotribology,” which functions in living organisms like artificial joints, “space tribology,” which operates in outer space like satellites, and “geotribology,” which studies earthquakes caused by friction between plates on the earth. The “cross-disciplinary” field of geotribology is very broad and includes a wide range of disciplines.

This is a “cross-disciplinary basic technology” that spans an extremely wide range of fields.

There is an episode that further illustrates the magnitude of the impact of tribology: About 60 years ago, the British government asked Professor Jost of Cambridge University to conduct a study to see how much energy could be saved through the management of lubrication. As a result, a report called the “Jost Report*1” was submitted, which said that 10% of the British national budget could be covered by optimizing lubrication. In addition to the direct benefits of reducing friction, indirect factors such as reducing machine maintenance costs and extending the service life of machinery and equipment were also included, for example, for a total economic benefit of 500 million pounds, or 500 billion yen at the exchange rate of the time. This is how the importance of tribology was recognized.

*1” Source:「 Fundamentals of Tribology」

Currently, as a project in this field, we are working on “creating a structure that facilitates lubrication by controlling the mechanical properties of parts and other surfaces that come into contact with each other.

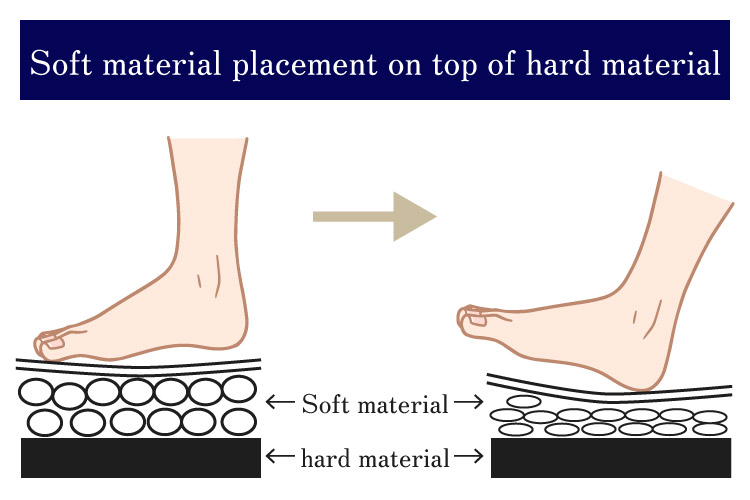

When you think of “slipping,” many people may think of slipping on a banana peel and falling, but this is not only the banana peel that causes slipping, but also the intrinsic lubricant that seeps out when you step on a soft banana on a hard, flat surface, which causes the peel to slip.

The aforementioned research theme, “Reduction of friction loss by creating a heterogeneous surface structure,” aims to realize a surface structure in mechanical parts that prevents oil film breakage by controlling and creating “heterogeneity,” just like a hard floor and a banana peel.

As a material for this, I am focusing on “sericite,” which is produced by Sanshin Mining. High quality sericite, which is used in cosmetics all over the world, has a high potential to become a very slippery material, and I have positioned it as a key item in this project. Specifically, we hope to form a new lubricating film by mixing sericite with soft metals and compounding it on the surface of conventional steel, castings, aluminum, or titanium alloys to create sliding surfaces that can function at high temperatures and in high vacuums such as outer space, where lubricating oil cannot be used.

We believe that this kind of technology can be applied to automotive parts and other fields that have a large number of parts that involve friction, wear, and lubrication. In the case of automobiles, the loss of a soft layer such as an oil film can cause breakdowns. By creating materials specialized for surfaces to prevent the loss of this soft layer, we hope to contribute to energy conservation in industrial society.

In particular, we are considering the possibility of creating “lubricating water” using “sericite” as a substitute for lubricating oil. Lubricating oil requires a lot of cost to dispose of, and I believe that using water will lead to energy conservation in industrial machinery, thereby reducing the burden on the environment, which in turn will fulfill the current theme of sustainability in the world.

Hatsuhiko Usami

Professor, Department of Materials Science and

Engineering, Meijo University

<Specialties>

Tribology, surface modification, material processing

<Awards>

Best Poster Award, American Ceramic Society

Distinguished Achievement Award, Japan Society of Mechanical Engineers (Mechanical Lubrication Design Division)

Fellow of the Japan Society of Mechanical Engineers

ICM&P2022 (International Conference on Materials and Processing, The Japan Society of Mechanical Engineers) Best Presentation Award

<Professor Usami’s URL>

Meijo University: Professor “Hatsuhiko Usami

Meijo University: “The 134th Hatsuhiko Usami” (Meijo University)

Contact us by e-mail

Please understand that we are unable to respond to inquiries from individuals as we only sell raw materials to suppliers.

This form is available 24 hours a day. Please understand that it may take some time for our respond to your e-mail.

If you do not receive an auto-reply e-mail or are in a hurry, please contact us by phone.

+(81)536-78-5511

- Using a free e-mail address

If you use a free e-mail address such as “gmail.com” or “yahoo.co.jp,” the server that provides the free address may restrict the receiving of e-mails, and you may not be able to receive e-mails even if the address is safe for general use. If you do not receive our e-mails, please check your junk mail box. - Due to the settings of your e-mail software

Your e-mail software or security software may have been set to automatically delete our e-mails. Please check your junk mail box. - In case there is a mistake in your e-mail address

Please check your email address to make sure it is correct. - If you have submitted mobile phone’s address.

Please check the “domain designation” setting in your cell phone’s e-mail receiving settings. We apologize for the inconvenience. Please check your settings to make sure that you can receive e-mail from a PC.